Lesson

Here is an easy silversmithing lesson on making a simple ring. I purchased my sterling silver at Thunderbird Supply Company. You can use pattern wire or 10 ga - plain wire. Use 1/2 - round sterling silver wire and easy flow, silver solder to solder it together. I buy my silver in ounces, instead of inches.

Supplies:

10ga - sterling silver plain wire or sterling silver pattern wire

Easy flow silver solder

Butane Torch and Butane

Handy Flux

Solder block

2 - Glass jars

Safety Goggles

Dusk Mask (optinial)

Disposable craft brush

Tweezers

Copper tongs

2 - glass jars

Distilled water

Dremel or other rotary tool

Flat file

Round nose and flat pliers (the ones without teeth)

Ring mandrel

Sharpie

Small paint brush for the flux

Rubber mallet

Bits: cut-off wheel, diamond bits (flat and skinny cylinder), rubber polishing bits, felt polishing cone

Pickle (sodium bisulfate: pH down for swimming poles)

Black, wet/dry 350 grit sand paper

Bleach (optional)

Jewelers rouge

Find your ring size, using a ring sizer. Wrap the silver wire, around a ring mandrel and mark the silver at the ring size, using a sharpie.

Don, your safety goggles and face mask (optional). If possible, hold your Dremel in your left hand. This will cause, most, of the debris to fall towards the ground and not your face.

Using a cut-off wheel, cut the wire a little longer that the mark.

Using a diamond bit or a jewelers, hand file, file the ends smooth and flush to the mark or a little smaller.

(Don't worry if the wire is a little smaller than the what you measured. At the end the ring will be pounded round, causing the ring to get a little larger.)

When the ends are held together, there should not be any light shinning through...solder does NOT fill GAPS!!

Wrap the silver around the ring mandrel and check the size. Using a pliers, flatten one side. This is what the ring should look like. The ends should be a tight fit. You may need to wiggle the silver ends back-and-forth, until the ends meet tightly.

Set up for soldering: flat file, Handy Flux, paint brush, small pieces of clean solder, small tweezers.

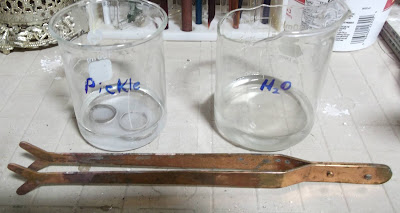

Also set up a glass container with your pickling solution, and anther jar with distilled water and copper tongs.

Using your brush, brush on a small amount of flux to the joint. Using the tweezers, add a small piece of solder to the joint.

Refill the torch with this instead of the cigarette lighter butane. This is far, cheaper. I bought this at Home Depot.

Place the ring on the soldering block. Slowly, start adding heat to the ring, using a sweeping motion. Do this until the flux is dries. Once the flux dries, concentrate the heat at the joint.

(Don't over heat your ring. The ring will turn red then melt.)

If your solder did not flow, either the ends weren't flush or the solder/flux was dirty. Once the solder flows, turn off the torch.

Using the copper tongs, ONLY, place the ring in the pickling solution for a few seconds. Using the copper tongs, ONLY, place the ring in the distilled water then remove and dry off.

Using your fingers, try to separate the seam. If the seam does not budge, you have a good soldered seam. If it breaks loose, re-file the edges and solder again.

Place the ring on the ring mandrel and hammer it round with a rubber mallet. If the ring is too small, keep hammering until the ring enlarges to the size. If too big, give the ring as a gift and try again...practice makes perfect.

Using a sharpie, mark the outside edge of the ring.

Using the wet/dry sandpaper, sand the edges flush. The sharpie ink will disappear when the edges are even.

Using a diamond bit (top bit) remove the solder from the inside of the ring and carefully remove any from the face of the ring. Using the rubber polishing point (bottom bit) remove any scratches.

Using these bits, may reduce your nails down to the finger tips. Just, part of the job.

Using a polishing buff and jewelers rough, polish the ring. You may want to wear a pair of nitrile gloves to keep your hands cleaner...especially if you are going to tat, later that day.

Clean the polish compound off with a household cleaner. If you want a patina on the ring (blacking the grooves), you can put the ring in a little bleach for a few seconds. At this point the whole ring will be blackened. Don't worry, re-polish the blackened part off. Polish, lightly over the grove work, so the patina remains in the groves.

Now, wear your ring proudly. I wear mine as an everyday wedding band.

No comments:

Post a Comment